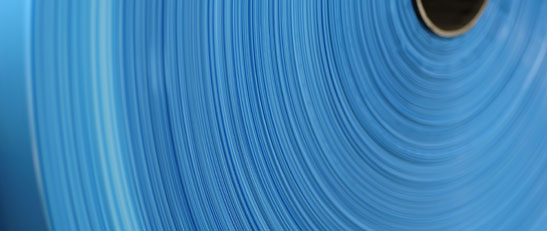

Flat film

We can offer our manufactured flat film, produced on the most modern food safe and environmentably acceptable equipment, in various shapes and sizes, like for example

Protective sheeting

Shrinkable flat film

Automat flat film

Coex flat film

Mono flat film � from first-class 1A new ware

Our portfolie comprises of various shapes and sizes for manual or automatic use also for flat film.

According to your requirement, the flat film will be manufactured with the corresponding shrinkable features (monoaxial or biaxial stretched) and if desired delivered needled. Of course, we will deliver the flat film also in the colours which you wish.

Our products, with the exception of refuse sacks, will generally be manufactured from first-class 1A new ware. We only deliver these with regenerated parts under specific customer request, in order to reduce costs.

Additives, such as for instance UV-stabilizer, static inhibitor and antiseize agents make sure that the flat film will exactly suit the customer�s requirements.

Multi-purpose applications

Flat film is not only applicable as a multi-purpose product precaution in the same way as tubular film, but serves when required as an advertisement area for the packed goods, with the desired customer printed design in up to 6 colours.

Coex flat film � Multi-layer procedure reduces costs

As also with the tubular film field, we have the possibility to deliver flat film in a multi-layer procedure.

This multi-layer procedure is somewhat more expensive at first sight than manufacturing of a mono film. The possible strength reduction of the film of up to 30%, however, sinks the ultimate costs of packaging considerably � with the consistent resp. partially better value of film.

Due to this reduction in material the shrinking time and thus the associated energy consumption will be sunken.

In addition, this procedure allows film to be manufactured with different qualitites on the outside and inside, such as e.g. outside anti-slip and inside slipable.

Also different colours on each side is realizable.

Products

Products