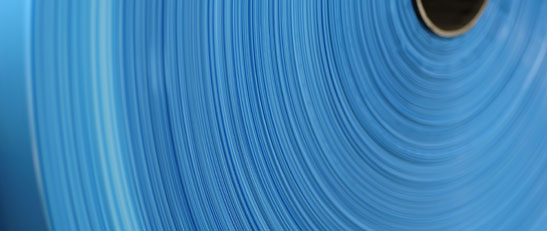

Tubular film

Mono tubular film

We deliver our tubular film, manufactured on the most modern euipment and from food safe and environmentally acceptable polythene, in many dimensions and designs, such as for example

Standard tube

Half tube

Flat tube

SF-shrinkable tube

All tubular film will be manufactured on demand with the corresponding shrinking features (monoaxial or biaxial stretched).

Tubular film on rolls allows, amongst others, the individual manufacture of bonnets and bags for packaging, to commission and as a safeguard of the merchandise to be packed.

Our products will generally only be manufactured from quality first-class 1 A new ware, with the exception of refuse sacks.

Of course we will also deliver the tubular film to you in the desired colour.

Additives, such as for example UV- stabilizer, static inhibitors and antiseize agents make sure that the tubular film exactly complies with the customer�s requirements.

Tubular film isn�t only applicable as a versatile product safeguard, but also serves the purpose of advertising space for the packed goods, when necessary, with the printed design desired by the customer.

Side gusset-shrinking tubular film offers a broad application spectrum

Due to our many years of experience in this product segment we work together with many happy and faithful customers from the industry today. The highly placed requirements put on ourselves with regard to quality and the constant dialogue with the fabricator forms our recipe for success.

SF-shrinkable tubular film from first-class raw materials, equipped with customer specified additives, as well as production possibilities of up to 6,000 mm total circumference guarantee a broad application spectrum for the industry.

The film with up to 6 possible printable colour varieties distinguishes itself, next to trouble-free manufacture, also optically through a high advertising effective appearance.

Coex tubular film � guarantee cost reduction

Of course it is further possible for us to deliver mono-extruded tubular film in coex quality, also multi-layered.

Dieses Mehrschichtverfahren ist auf den ersten Blick etwas teurer als die Fertigung einer Monofolie. Jedoch die St�rkenreduzierung der Folie von bis zu 30 %, senkt die Kosten f�r die Verpackung erheblich, bei gleich bleibenden bzw. teilweise verbesserten Werten der Folie.

Due to this material reduction the shrinking time and also therewith the related energy use will be sunken.

In addition this procedure allows film with different qualities for outside and inside to be manufactured, such as e.g. outside anti-slip and inside slipable.

Also different colours on each side is realizable.

Hood-stretched tubular film / ductile tubular film

Due to the stretch procedure a flexible tube will be produced, which when stretched, will be pulled over the goods to be saved and pallet pulling these together. Consequently a safe hold between the pallet and goods will be warranted.

The advantages of this film lays in the reduced film usage. This results from the ductibility, an optimal visualization of the goods, as well as reduced energy costs and the omission of shrinking processes by an open flame.

We are only too happy to answer your questions.

Contact

Phone: 09154-91132-105

Email: verkauf@hemiplast.de

Products

Products